Nigam Industry is a reputed name in industrial safety gloves. Our products are made with hi-tech machinery. We are offering a wide range of industrial gloves for various applications depending upon different specifications and requirements.

In order to give a quick view of glove structure and manufacturing specifications, we are sharing our Gloves Guide so that you may get more out of your pair of gloves.

Leather gloves are best for protection from rough objects, sparks, and heat, and for cushioning from blows in heavy-duty work environments. All kinds of leather provide comfort, durability, dexterity, mild heat resistance and abrasion protection. These advantages make leather a traditional favourite for industrial workers.

Styles & Patterns in Nigam Industry:

• Leather Palms, Gunn Patterns – For protection from rough objects, sparks, heat and cushioning from blows in heavy-duty work environment.

- Leather Palms, Clute Patterns – Greatest economy glove offering superior leather protection.

- Drivers – These gloves allow more dexterity when operating heavy machinery and vehicles.

- Welders – Welders provide protection during welding and heat applications.

- Mig/Tig Welders – These gloves afford a fine touch during low heat applications.

Types Of Leather :

Elite Leather Creations work with the following types of leather:

• Cow Leather :

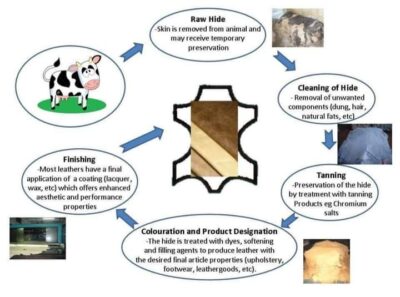

Cow leather is the most commonly used leather within the glove industry due to its plentiful availability. The United States and Australia produce the majority of these hides. The advantages include comfort, durability, excellent abrasion and breathability. Chrome tanning of this leather provides greater wear and heat resistance.

• Goat Leather :

Independent tests have proven goat leather to be a stronger and more durable leather. The natural lanolin produced by goats helps to create the softest, most abrasion-resistant products. This leather is highly recommended for applications requiring tactile sensitivity.

Cuts Of Leather :

- Grain – Grain leather is the smooth external side of the hide. This type of leather provides durability and dexterity

- Split – Split leather is the rougher internal side of the hide. The three different types of split leather are side, shoulder or belly splits.

- Side Split – comes from the rib area of the animal. This part of the leather is more durable and provides the greatest protection because of its greater density of fibres

Shoulder Split – is more economical than the side, but less durable. The additional movement in this shoulder area creates fewer fibres and a more visible texture difference.

Belly Split – is the most economical; however, it has the least consistency of texture and appearance

Types of Leather :

• Cow :

Cow leather is the most commonly used leather within the glove industry due to its plentiful availability. The United States and Austrailia produce the majority of these hides. The advantages include comfort, durability, excellent abrasion and breathability. Chrome tanning of this leather provides greater wear and heat resistance.

• Goat :

Independent tests have proven this to be a stronger and more durable leather. The natural lanolin produced by goats helps to create the softest, most abrasion-resistant leather. This leather is highly recommended for applications requiring tactile sensitivity.

Parts of the hide:

Leather is a grown material, it doesn’t come from a roll, every leather is different, and the area is measured on an average mass of each individual piece. Tolerance levels of ± 30% are therefore normal. Due to this, prices are only relative, for example 39, 00 €/m² is listed. The exact price for a piece is always given separately.